Iljin Metal Industry Co., Ltd.

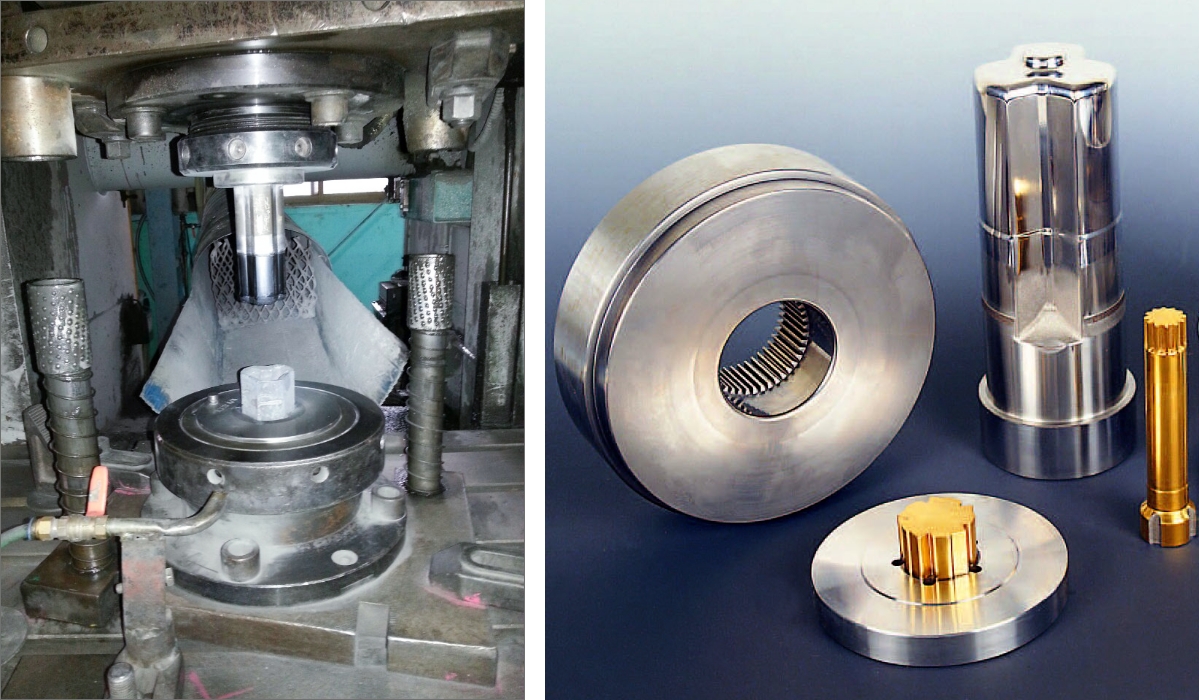

With a range of presses from a 2,000-ton large warm and cold press to a 200-ton small press, we deliver customer satisfaction by producing high-quality cold and hot forging products across various industries.

| Division | Equipment name | MARKER | Standard |

|---|---|---|---|

| Warm forging | 2000TON PRESS | KURIMOTO | C2F-20GWL |

| 1600TON PRESS | VORONEZH | ||

| 1600TON PRESS | KOMATSU | ||

| 1250TON PRESS | SCHULER |

With a range of presses from a 2,000-ton large warm and cold press to a 200-ton small press, we deliver customer satisfaction by producing high-quality cold and hot forging products across various industries.

| Division | Equipment name | MARKER | Standard |

|---|---|---|---|

| Cold forging | 2000TON PRESS | NEAGARI | NCH-2000 |

| 2000TON PRESS | Dongmyeong Industrial Machinery | TCF-2000-TM01 | |

| 1300TON PRESS | SACK & KIESSELBACH | OKP1250 | |

| 1200TON PRESS | HANOUL | HNKJ-1200S | |

| 1000TON PRESS | AIDA | CFI-1000 | |

| 1000TON PRESS | HANOUL | HNKJ-1000 | |

| 630TON PRESS | AIDA | K-630 | |

| 630TON PRESS | KOMATSU | LIC630-2 | |

| 400TON PRESS | Jeil Heavy Machinery | JKP-400 | |

| 200TON PRESS | HANOUL | HNCP-200 |

We operate our own non-oxidation annealing furnace, enabling a non-oxidation annealing heat treatment process during forging operations.

| Equipment name | Spec |

|---|---|

| Non-oxidizing annealing furnace | 2.5 Ton/Batch |

We have our own lubrication line to provide lubrication during the forging process.

| Equipment name | Spec |

|---|---|

| Lubrication equipment | 0.5 Ton/Batch |

| 1 Ton/Barrel | |

| SHOT BLAST | 0.5 Ton/Batch |

| 1 Ton/Barrel |

We manufacture optimal molds with our own mold design system and production facilities.

| Equipment name | Spec |

|---|---|

| Lathe | WL 460 × 1000 |

| WL 420 × 1500 | |

| WL 580 × 1500 | |

| MILLING M/C | WMTU 1100 |

| DMB-1500 | |

| RADIAL DRILLING M/C | DRD-1500 |

| UNIVERSAL GRINDER | GUP 32 × 100 |

| GUP 270 × 500 | |

| Automatic plane grinding machine | DSG-500H |

| Forming grinding machine | DSG-450H |

| WIRE CUTTING E.D.M | FANUG MATE A04B |

| ELECTRIC DISCHARGE M/C | EHWA MT-30 |

| WLTRASONIC FINISHER | DUAMAX Ⅱ |

| ULMAX Ⅱ | |

| TOOL GRINDER | TG-46 |

| QUENCHING FURNACE | 40kW/600×600×900 |

| TRAVEL(X,Y,Z) | 350×250×250 |

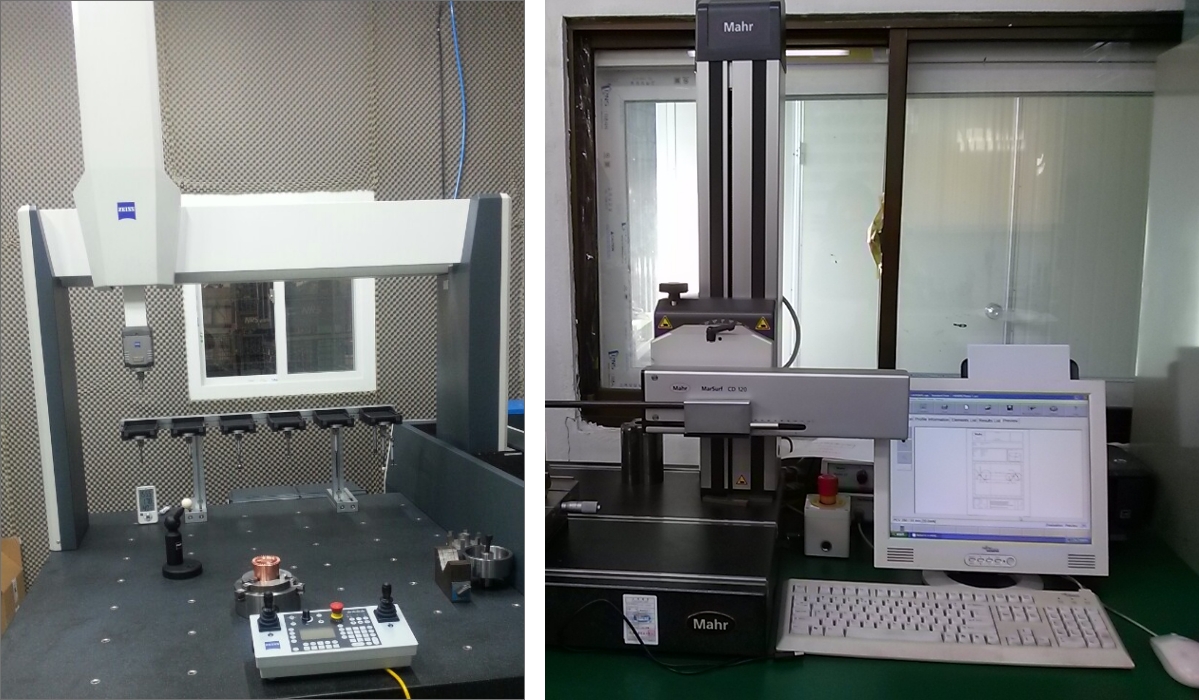

We have coordinate measuring machine and other inspection equipment to guarantee the quality of our products.

| Equipment name | Spec |

|---|---|

| Coordinate Measuring Machine | WL 460 × 1000 |

| Ingredient Analyzer | WL 420 × 1500 |

| Contour Meter | WL 580 × 1500 |

| Surface Roughness Tester | WMTU 1100 |

| Roundness Measurer | DMB-1500 |

| Metallographic Microscope | DRD-1500 |

| ROCKWELL Hardness Tester | GUP 32 × 100 |

| BRINELL Hardness Tester | GUP 270 × 500 |

| Bierkus Hardness Tester | DSG-500H |

| Magnetic Particle Detector | DSG-450H |

| Vertical Profile | FANUG MATE A04B |